At LJ Design & Manufacturing, we understand the unique demands of the medical industry—where precision isn’t a preference, it’s a requirement. Our team delivers high-quality, custom-sewn solutions that meet the rigorous standards of medical applications.

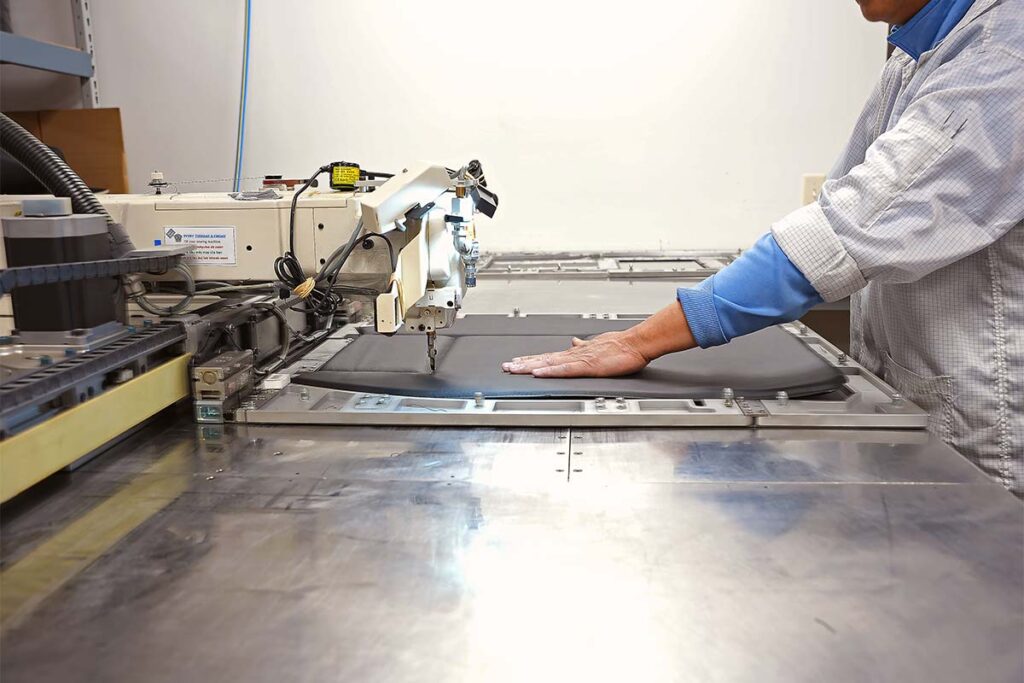

With decades of experience in industrial sewing, textile integration, and contract manufacturing, we’re uniquely equipped to support OEMs and medical device companies through every stage of production. Our capabilities include textile cutting, precision sewing, and complex assembly—all executed with an unwavering focus on consistency and quality.

Whether you’re developing patient-facing products or internal-use components, we collaborate closely with your engineering and sourcing teams to ensure every part is built to spec and ready for regulatory review.

Our Midwest-based facility offers the scale and flexibility to support both low- and high-volume production runs. As an FDA-registered medical device contractor, we tailor our quality control processes to meet the traceability, documentation, and compliance needs of the medical sector.

LJ Design & Manufacturing is your trusted partner—delivering precision craftsmanship and responsive support to help bring your medical products to life.

FDA Medical Device Manufacturing

L&R USA is a leading international supplier of medical devices and hygiene products, including custom therapeutic garments for lymphedema and venous disease. They wanted to expand their product line to offer standard size products. They needed a partner that was able to provide strict quality controls and meet FDA requirements as an FDA registered medical device contractor. It was important that they had a consistent and repeatable manufacturing process to create standard size garments.

Medical-Grade Quality

Our established ISO compliant quality control system provided them with the documentation needed for an FDA regulated medical device contractor. Our automated, programmable sewing capabilities [link to contract sewing] provided the consistency and repeatability necessary for their standard sizes. We were easily able to accommodate their volume requirements as they continued to scale and launch the products to their distributors.