As an FDA registered medical device manufacturer, we are fortunate to partner with a wide variety of medical device manufacturers from large, well established healthcare companies, to up-and-coming MedTech innovators.

Your innovations save lives, improve patient care and outcomes and increase the wellness of our communities. This means everything must be manufactured to the highest standards. Period. Our goal is to be a true partner with you. Our team is your team.

Our entire team from engineering, to production has deep experience making sewn products for the unique demands of the healthcare industry. That’s why our medical customers particularly value our rigorous quality control process, thoughtful design improvements and precise manufacturing capabilities.

Applications

- Medical device cases & bags: Medical devices often require portability. A soft, custom fit case keeps your device secure when on the go.

- Compression garments: Compression therapy is a long-proven method of treatment for a number of conditions. There are a number of design techniques for ensuring consistent, reliable compression.

- Patient restraint straps: Restraint straps keep patients and healthcare providers safe. It is critical that they are reliably strong and durable use after use.

- Medical kits and cases: Medical supplies of all types are vital to patient care. Keeping them organized and easily available in a soft kit or case reduces potential delays and confusion during treatment.

- Medical pads and cushions: Pads and cushions are often used to support patients during procedures or provide relief and comfort while healing.

Markets using LJ Design & Manufacturing

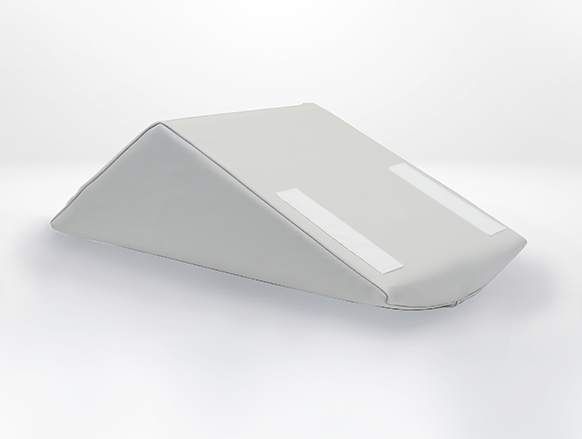

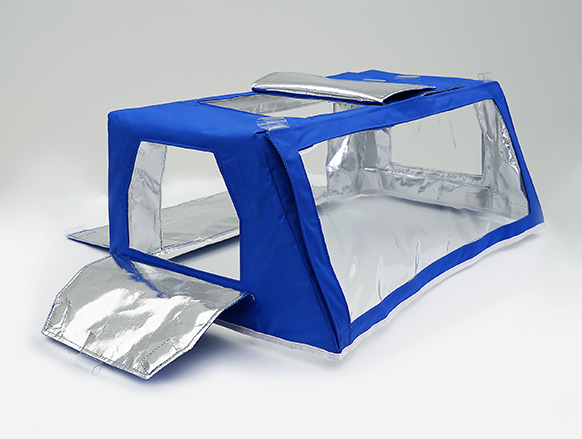

Thermal Incubator Cover

International Biomedical’s innovative line of incubators plays a vital role in neonatal and perinatal care, helping maintain a stable, controlled environment for the most vulnerable patients. One essential component? The thermal cover, which helps maintain optimal temperature and reduce heat loss.

When their previous manufacturer retired, International Biomedical needed a new partner who could not only replicate the product but improve upon it. LJ Design & Manufacturing was already producing low-volume sewn items for them, making us a natural choice to take on the more complex thermal cover.

Engineering Know-How

As with all new projects, this one began with a technical deep dive from our engineering team. The thermal cover needed to include multiple easy-access points, allowing caregivers to interact with both the incubator and infant without removing the entire cover—minimizing heat loss and maintaining stability….